Comprehensive branch competencies

Medical Devices

Automotive

Building Technologies

Industry

Injection Moulding Competences for Medical Devices

We have been developing plastic parts and subassemblies together with our customers for medical devices for many years.

The parts produced for customer specific solutions have reached smallest dimensions while still fullfilling highest requirements. Our production processes are validated and our cleanroom classified level 7 is verified according to ISO 14644. Our framework of competences reaches from two component processes and internal gas preasure technology to fully assembled, individual packed, steriliesed and verified plastic parts.

The production of housings, visual parts and translucent parts made of perspex are part of our portfolio as well as the subassembly by pad printing, laser isncriptions and soft touch surface finishes. We can cover most areas of medical technologies by using special material containing protection against flammability or chemical resistance as well as bio compability.

Consultation

Is the most beneficial solution for your requirement injection moulding?

Development

The perfect tool and the best process for your plastic solution.

Clean Room

High quanity injection moulding while guaranteeing consistant high quality.

Logistic

We deliver reliable and on time: just in time or just in sequence

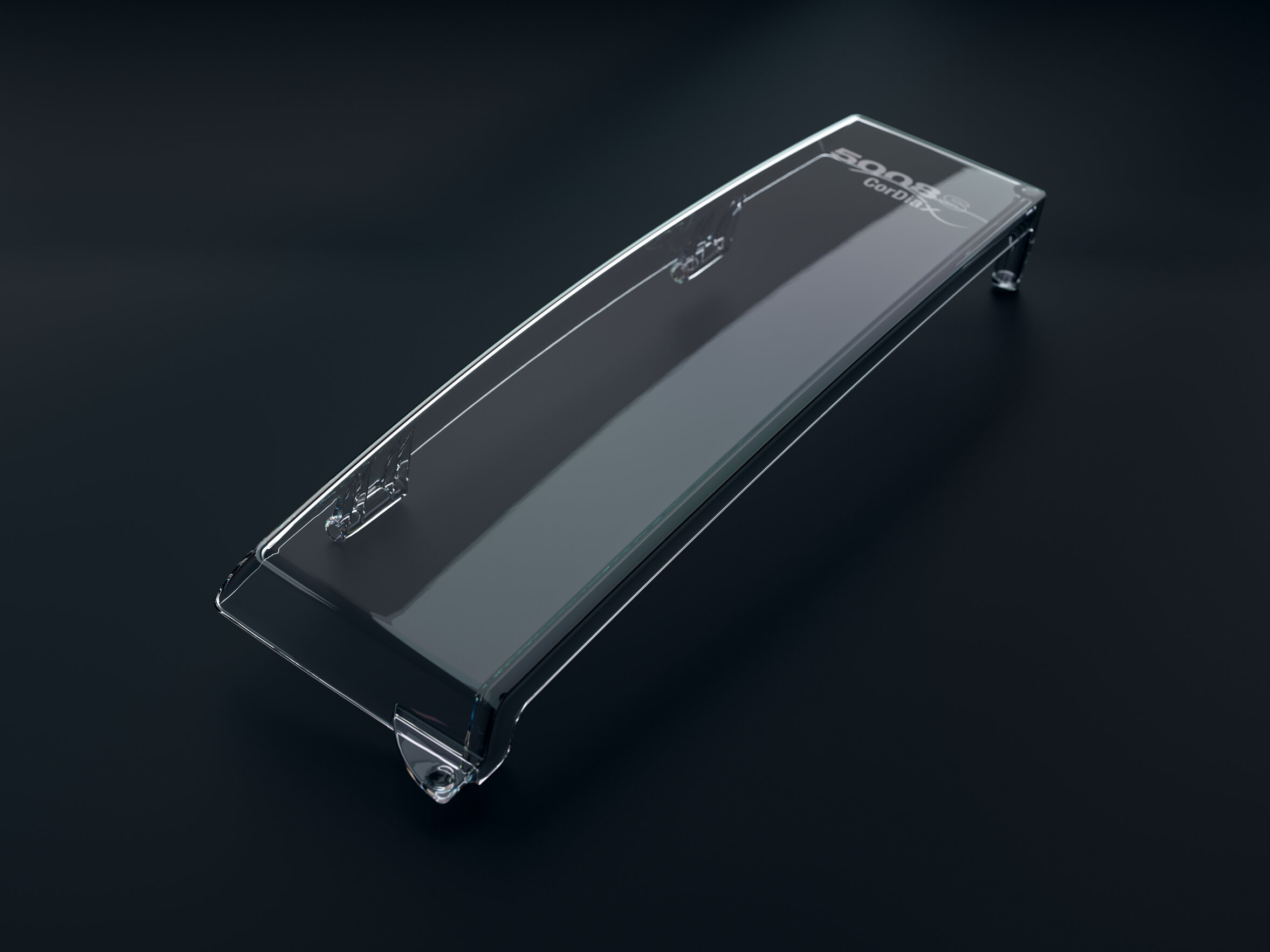

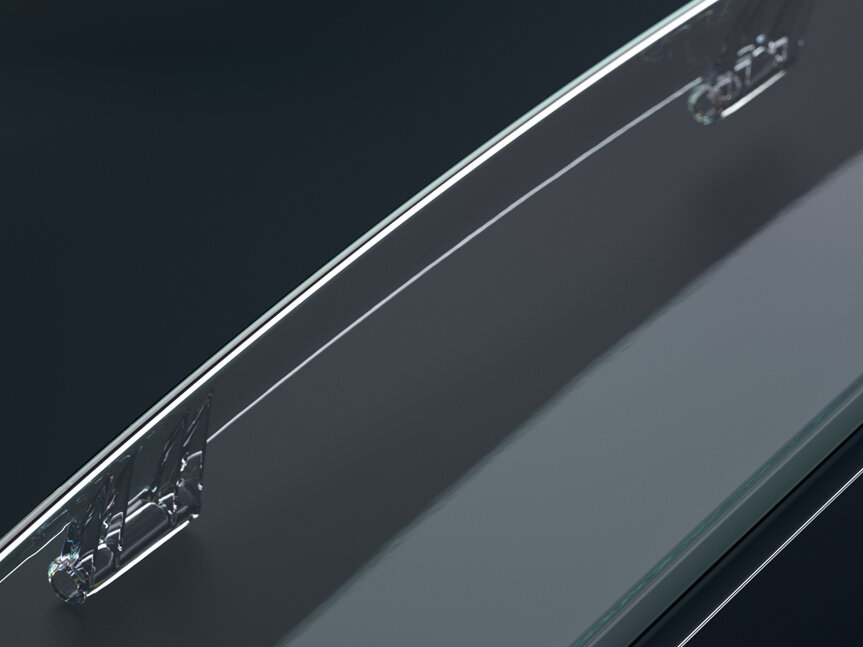

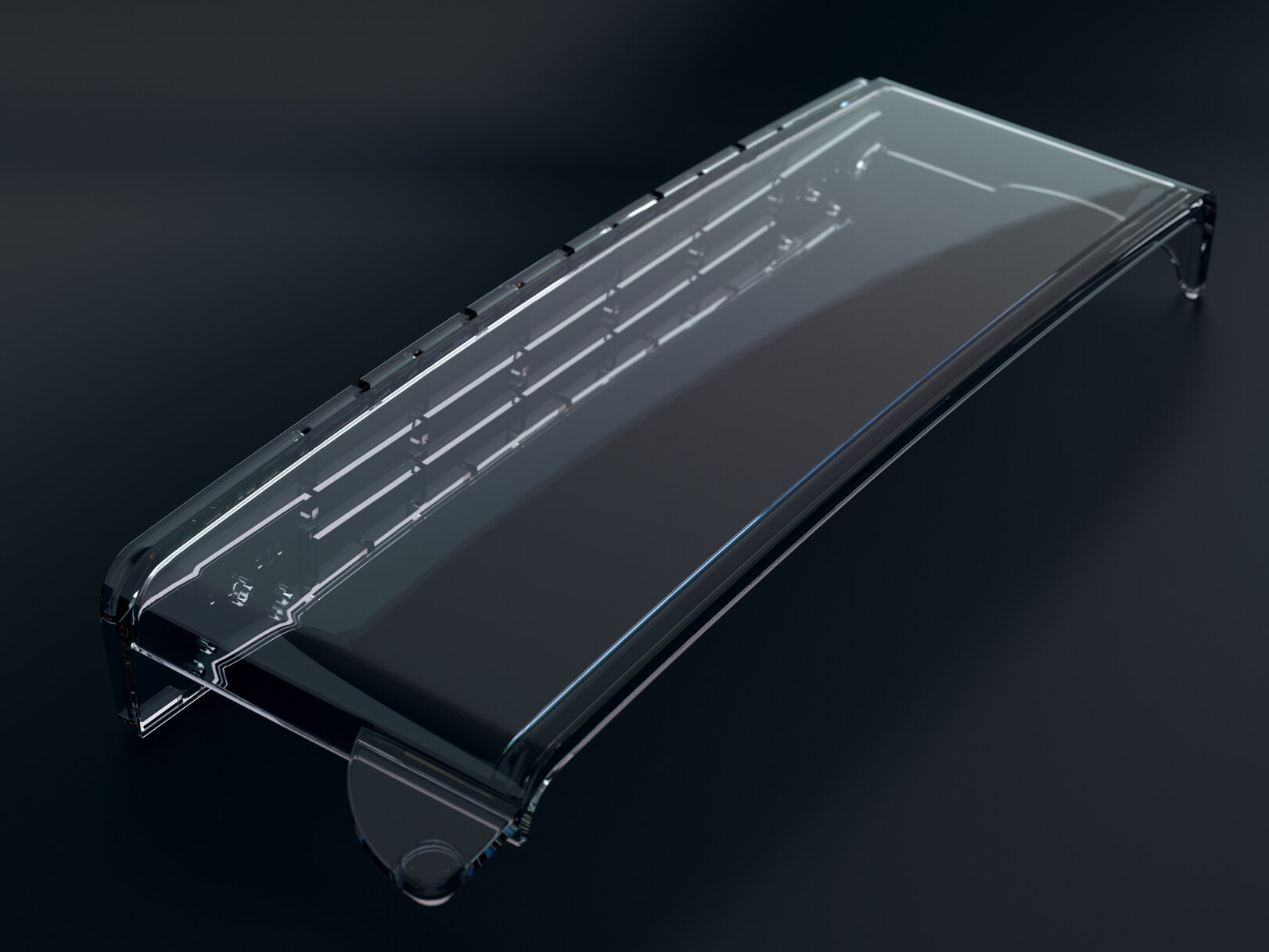

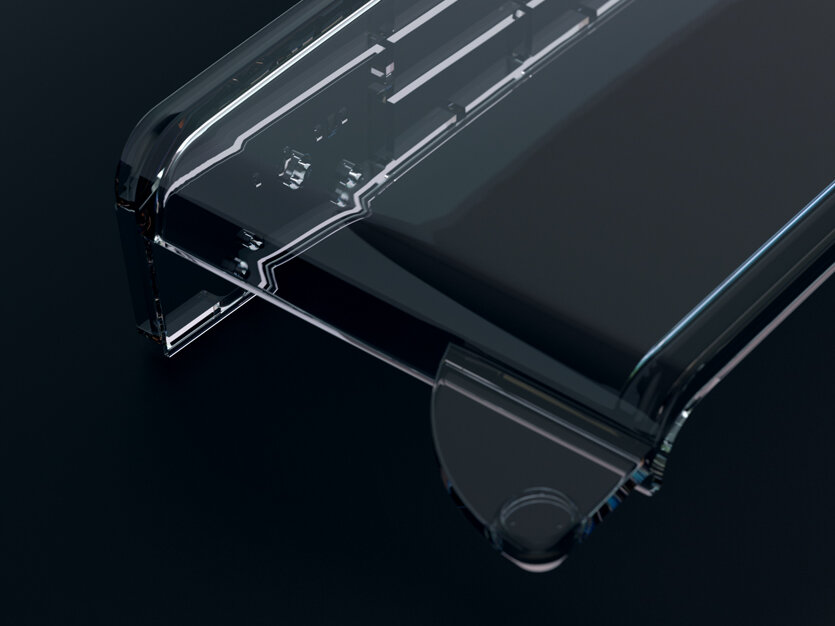

Scratch and blood resistent

Multi Component solutions developed together with the customer

Softtouch surfaces for quick and reliable controls

Blood resistant doors for display devices in hospitals

Crystal clear and scratch resistant thanks to special anto scratch finishings

Glasklar und kratzfest

Certified quality in all procedures and processes

Your solution benefits from injection molding?

Are you looking for a reliable, high-quality solution for your medical device or instrument? Then ask us!

Kunststoff Christel GmbH & Co. KG

Phone: +49 7726 9202-0

Fax: +49 7726 9202-8110

E-Mail: info@kunststoff-christel.de